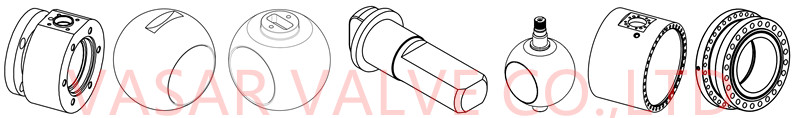

Metal seated valve ball and seat is the critical parts of metal seat ball valves. It is designed for extreme high pressure and temperature applications, such as cutting off or connecting solid granules, melted slurry, coal power, fervent cinder, steam water or other liquid etc. Therefore, it has the feature of anti-static construction, extra tough coating, full bore and reduced bore, fire safe feature complying API607, and reliable sealing performance. We have both thermal spray coating and cold spray coating available such as Laser Cladding,HVOF Coating,Oxy-acetylene flame spray,Plasma Spray process.

We are able to supply coating including Tungsten Carbide, Chrome Carbide, or Stellite coatings,Ni60. The seat is also designed in ANSI B16.104 with wear resistant, impact resistant, and pressure relief.

Ball and Seat Lapping

We also provides complete valve ball+seat kits solution to customers. Over the years, Vasar has developed a unique ball lapping technology for the coated ball and seat. Through simultaneous same and different direction of rotation, the ball and the seat result in perfect roundness and fitness, achieving ‘Zero Leakage’