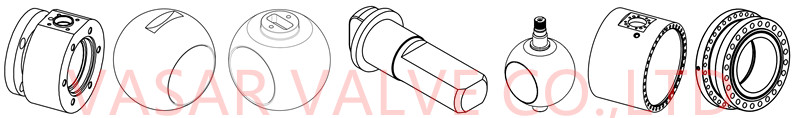

304 Stainless Steel Valve Ball

304 is the most widely used austenitic stainless steel, and it's also known as "18-8" stainless steel because of its composition – it includes 18 percent chromium and 8 percent nickel.Type 304 stainless steel has good forming and welding properties, as well as strong corrosion resistance and strength. It also has good drawability. It can be formed into a variety of shapes and, in contrast to type 302 stainless, can be used without annealing.

304L Stainless Steel Valve Ball

304L stainless steel is an extra-low carbon version of the 304 steel alloy. The lower carbon content in 304L minimizes deleterious carbide precipitation as a result of welding. 304L can therefore be used "as welded" in severe corrosion environments and it eliminates the need for annealing.

This grade has slightly lower mechanical properties than the standard 304 grade, but it's nonetheless widely used thanks to its versatility. Like Type 304 stainless steel, it's commonly used in beer-brewing and wine-making, but also for purposes beyond the food industry such as in chemical containers, mining and construction. It's ideal for use in metal parts such as nuts and bolts that will be exposed to salt water.

Type 304 and 304L Stainless Steel Composition:

| Element | Type 304 (%) | Type 304L (%) |

| Carbon | 0.08 max. | 0.03 max. |

| Manganese | 2.00 max. | 2.00 max. |

| Phosphorus | 0.045 max. | 0.045 max. |

| Sulfur | 0.03 max. | 0.03 max. |

| Silicon | 0.75 max. | 0.75 max. |

| Chromium | 18.00-20.00 | 18.00-20.00 |

| Nickel | 8.00-12.00 | 8.00-12.00 |

| Nitrogen | 0.10 max. | 0.10 max. |

| Iron | Balance | Balance |