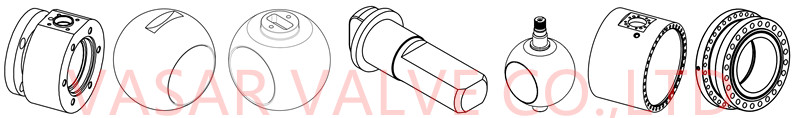

Ball Valve Seat Specification

| Pressure Rating | 150lb,300lb,600lb,900lb,1500lb,2500lb |

| Nominal Size |

2”,2 1/2”,3”,4”, 4 1/2”,5”,6”,7”,8”,9”,10”,12”,14”,16”,18”, 20”,22”,24”,26”,28”,30”,32”,34”,36”,38”,40”,42”,44”,46”,48” |

| Materials |

Carbon steel, stainless steel, cryogenic steel and special alloy. ASTM A 105, A350 LF2, A182 F304, A182 F316, A182 F6A, Duplex A182 F51, A182 F53, A564 630 (17-4PH), Inconel 625, 690, 600, 617, 718, 718 SPF, Monel 1400, R-405, K-500, Titanium Gr3, Gr4, Gr7, Incoloy 800, 825, 903, 907, Hastelloy C serial, B etc |

| Coating |

Thermal Spray and Cold Spray: Nitridation, ENP, Chrome Plating, HVOF Tungsten Carbide, HVOF Chrome Carbide, Stellite 6# 12# 20#, Inconel, etc |