Electroless nickel plating is an alloy of nickel and phosphorous.

Electroless Nickel Plating(ENP) Ball has been widely applied in valve ball production with its advantages such as simple processing, low-cost, uniform thickeness and large-area plating. Many clients will specify A105/ENP because they believe it to be a more cost effective option than a full stainless steel ball. The other advantage is that there is no plating to come off! Whilst the surface hardness of the ENP is quite high, the strength of the substrate is often the limiting factor, especially in the instance where line scale, sand or similar is caught between ball and seat. Once the ENP coating is compromised a failure will not be long in coming.

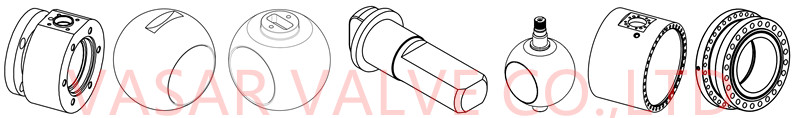

ENP Plating Valve Balls Specification

| Base materials | Carbon steel |

| Phosphorus (P) | 10.5 % up to 13% |

| Nickel (Ni) | balance |

| All other elements (total) | 0.05 % maximum |

| Thickness | 25µm,50µm,75µm |

| Hardness | 500-1300 Hv. |

| Tests | ASTM B733, such as: hardness, thickness, corrosion resistance, burning, bending, adhesion etc. |