We can provide complete solution for Corrosion Resistance & Hard Facing application by Weld overlay process.The main purpose for weld overlay is its use for corrosion resistance or wear resistance.

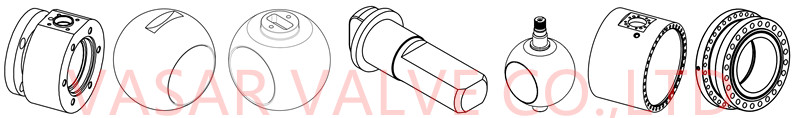

Manufacture of Weld Overlay Valve Components as per Customers Requirements and Specifications. We Supply Weld overlay of ss316,Inconel and stellite on Valve Balls, Stem, Stem Housings, Globe Valves, Ball Valves and stelliting on Butterfly Valves and Gate Valves All Cladding is as per Standards.Weld overlay is a welding process where one or more metals with specific characteristics are applied to a base metal to improve desirable properties or to restore the original dimension of the component.Weld overlay may also be referred to as cladding, hard facing, weld cladding or weld overlay cladding.

Weld Overlay Capabilities

Nickel Alloys – 200, 400, 625

Wear Resisting Alloys – Stellite 21, Stellite 06